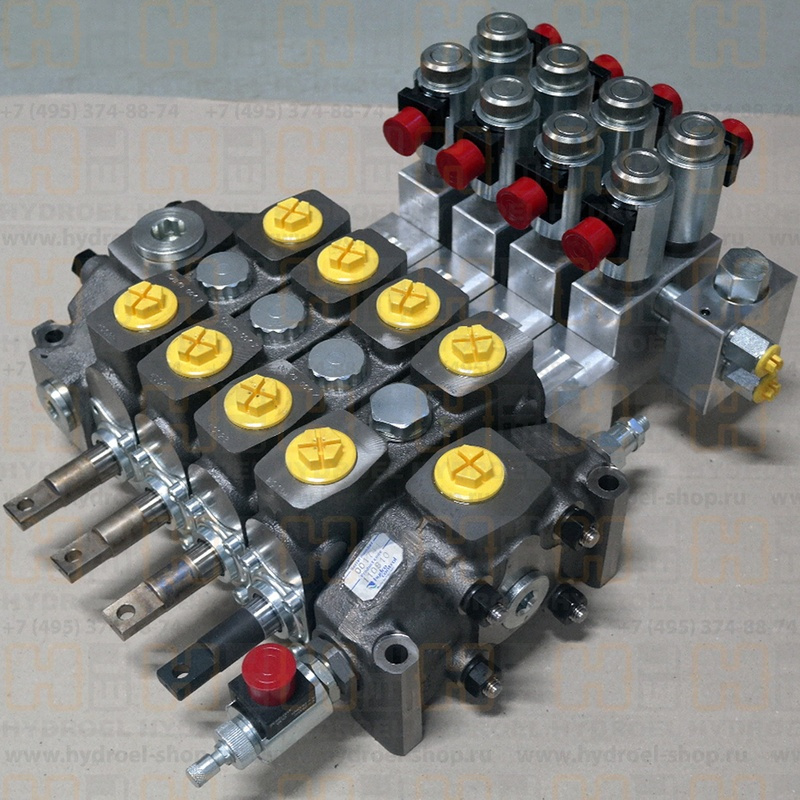

The Hydrocontrol HC-D16/6 is a robust hydraulic directional control valve engineered for complex mobile machinery. As a key model in the HC-D16 series, this hydraulic component is designed to manage multiple actuators with precision and reliability. It operates at a rated pressure of 350 bar and handles flows up to 160 L/min, making it a powerhouse for demanding applications in construction, material handling, and specialized vehicles. Its modular, sectional architecture allows for custom configurations, providing system designers with unparalleled flexibility to tailor the valve stack to the exact needs of their equipment.

Hydrocontrol S.p.A. has been a stalwart in the hydraulic components industry since 1969, specializing in solutions for mobile machinery. The company's core philosophy is to provide complete "hydraulic control systems for moving machinery"—a focus that has made it a trusted partner for OEMs in sectors like earthmoving, agriculture, and forestry. This long-standing expertise is embedded in the design and manufacturing of the HC-D16 series, ensuring each valve is built to perform reliably in the most challenging operating environments. Choosing a Hydrocontrol product means leveraging decades of Italian engineering dedicated to innovation and quality.

The Hydrocontrol HC-D16/6 directional control valve incorporates several key features that make it a high-performance component in hydraulic circuits.

Modular Sectional Design: The valve uses a split-section (sandwich-type) architecture. The "HC-D16/6" denotes a 6-section valve, but the series supports 2–10 sections. This modularity lets designers create custom valve stacks that match the exact number of hydraulic functions required.

Robust Performance Parameters: Built for high-pressure systems, it has a nominal working pressure of 350 bar and handles flows up to 160 L/min—suitable for medium-to-high flow applications. The cast iron body ensures durability and long service life under strenuous conditions.

Versatile Spool Functions & Control Options: Offers various spool configurations to tailor actuator behavior. It supports multiple control methods: manual levers, hydraulic pilot control, and electro-hydraulic control—enabling integration into simple or sophisticated machine systems.

Integrated Auxiliary Valves: Each section can be equipped with ancillary valves (e.g., overpressure relief valves for actuator protection, anti-cavitation check valves) to enhance system safety and performance.

Parameter

Specification

Model Series HC-D16

Specific Model HC-D16/6 (6-section valve)

Rated Pressure 350 Bar

Maximum Flow 160 L/min

Construction Sectional (Split-type)

Material Cast Iron

Control Methods Manual, Hydraulic Pilot, Electro-Hydraulic

Understanding the Technology: The Role of a Directional Control Valve

A hydraulic directional control valve acts as the "central nervous system" of a hydraulic circuit. Its primary role is to direct hydraulic fluid to various actuators (cylinders, motors), controlling their start, stop, and movement direction.

The HC-D16/6 belongs to the sectional (stackable) valve category—distinct from monoblock valves. Its "building block" design uses multiple identical sections bolted together, offering key advantages:

Scales functionality precisely to the application.

Reduces inventory complexity (standard sections work across models).

Provides greater design freedom than fixed-configuration monoblock valves.

Key Application Areas and Operational Value

The Hydrocontrol HC-D16/6 excels in mobile equipment, leveraging its robustness and flexibility for:

Construction & Earthmoving Machinery: Wheel loaders, backhoe loaders, and excavators—where precise, simultaneous movements drive productivity.

Specialty Vehicles & Drilling Equipment: Rotary drilling rigs, refuse collection vehicles, and tow trucks—reliable control for complex workflow cycles.

Material Handling: Boom trucks and cranes—ensures safe, controlled lifting operations.

Consolidates multiple control functions into a compact stack, reducing leak points and simplifying piping.

Simplifies serviceability (modular sections are easier to access).

Lets OEMs balance control type (manual/automated) with cost and machine requirements.

New Section: Key Considerations for Selection and System Integration

When selecting the HC-D16/6, designers must look beyond section count:

Spool Type: Specify spool configuration (e.g., open center, closed center, float) for each function to ensure desired actuator behavior.

Control Method: Choose based on machine complexity—manual levers (cost-effective for simple systems), hydraulic pilot/electro-hydraulic control (for automation/joystick operation).

Auxiliary Valves: Plan for relief valves or check valves during initial design to protect actuators and avoid costly post-installation modifications.

New Section: Comparing Sectional and Monoblock Valves

Understanding trade-offs between sectional (HC-D16/6) and monoblock valves ensures optimal selection:

Aspect

Sectional Valves (HC-D16/6)

Monoblock Valves

Flexibility High—add/reconfigure sections for custom functions; 2–10 sections supported. Low—fixed number of functions (no post-installation changes).

Cost Efficiency Better for custom/low-volume machines (avoids full valve replacement). Cheaper for high-volume, standard applications (single cast unit).

Scalability Future-proof—add sections if machine functions expand. Requires full replacement for design changes.

Size/Weight Slightly larger (stacked sections) but more compact than multiple standalone valves. More compact for the same number of functions (single unit).

For custom machinery or applications needing scalability, the HC-D16/6’s sectional design is superior; monoblocks work best for standardized, high-volume equipment.

Its primary role is to direct hydraulic fluid to actuators (cylinders, motors), controlling their start, stop, and movement direction. The HC-D16/6 uses multiple spools (one per section) to manage separate hydraulic functions, enabling coordinated operation of complex machinery (e.g., excavator arm + bucket movements).

Exceptional flexibility and customizability:

Build valves with exactly the number of sections needed (2–10) instead of fixed counts.

Simplifies inventory (standard sections work across machine models).

Future-proofs designs—add sections if new functions are required, no full valve replacement.

It is widely used in medium-to-heavy-duty mobile equipment, including:

Construction: Wheel loaders, excavators, backhoe loaders.

Specialty vehicles: Rotary drilling rigs, refuse trucks, tow trucks.

Material handling: Boom trucks, cranes (for controlled lifting).

Modularity cuts costs at every stage:

Inventory: Stock standard sections instead of multiple full valves for different models.

Design Changes: Add a section for new functions (no full valve replacement).

Maintenance: Service faulty sections individually (minimizes downtime and repair costs).

Long-term reliability depends on:

Fluid Cleanliness: Contamination is the top cause of failure—use high-quality filters and follow strict fluid change schedules.

Leak Checks: Regularly inspect for external leaks (loose connections, seal wear).

Performance Monitoring: Watch for signs of issues (slow actuator movement, erratic behavior) to address problems proactively.