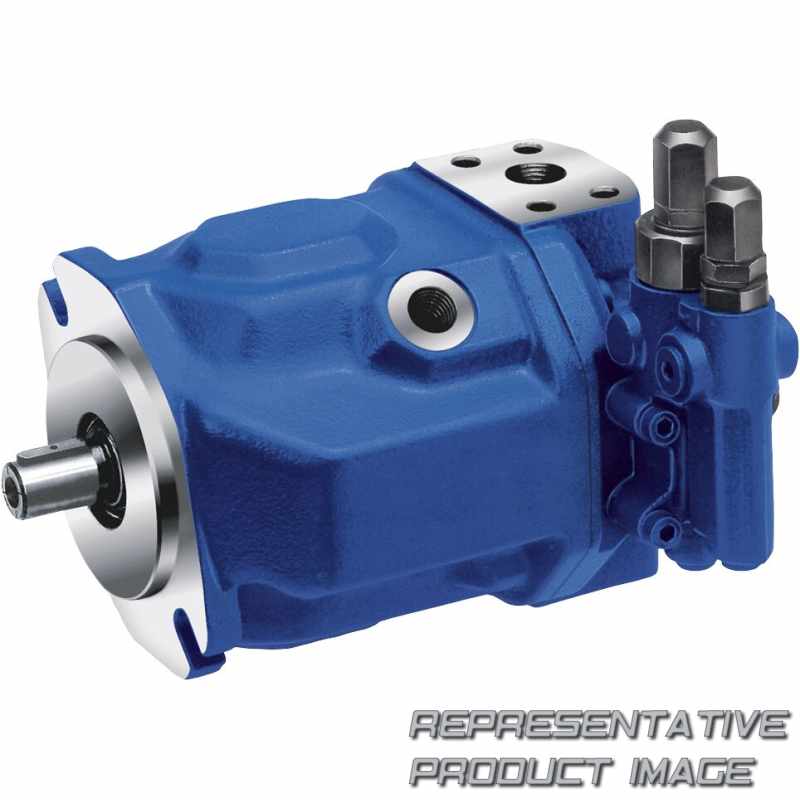

The Rexroth A10VSO 28 DFR1/31R-VPA12N00 is a premier example of advanced hydraulic pump engineering,specifically designed as an axial piston variable pump for open-loop circuits.This hydraulic piston pump leverages a swashplate design to deliver exceptional performance,reliability,and control versatility.With a nominal displacement of 28 cm³per revolution and the capability to handle continuous pressures up to 280 bar,it is built to meet the rigorous demands of modern industrial and mobile applications.Its core functionality revolves around varying the pump's displacement by adjusting the angle of the swashplate,allowing for precise and efficient control of the hydraulic power output.This pump is particularly recognized for its low noise operation,high power-to-weight ratio,and rapid control response,making it an ideal choice for systems where energy efficiency and dynamic performance are critical.

1.In-Depth Technical Profile and Performance Envelope

The A10VSO 28 DFR1/31R-VPA12N00 is defined by a set of robust technical parameters that underscore its capability for high-performance applications.The pump operates with a nominal pressure of 280 bar and can withstand peak pressures of up to 350 bar,ensuring reliability under transient load conditions.The maximum theoretical flow output is approximately 42 liters per minute,a value directly proportional to the 28 cm³/rev displacement and the driven speed of the pump shaft.

This model is designed for a broad range of operating speeds and is compatible with standard industrial drive motors.A key aspect of its specification is the requirement for high-quality hydraulic fluid with a cleanliness level of at least NAS 1638,Class 9,to ensure long service life and maintain the precision of its internal components.The pump is constructed with a cast iron body,providing durability and structural integrity,and features FKM(Fluorocarbon Rubber)seals as standard,offering excellent resistance to a wide range of hydraulic oils and high operating temperatures.Weighing approximately 17.78 kg,it maintains a compact and space-efficient design.

2.Core Design Philosophy and Operational Mechanism

As a swashplate-type axial piston variable pump,its operation centers on a cylinder block that houses several pistons.These pistons are connected to a driveshaft and their slipper pads bear against a stationary,but angularly adjustable,swashplate.As the driveshaft and cylinder block rotate,the fixed angle of the swashplate forces the pistons to undergo a reciprocating motion within their respective bores.This creates a cyclic process of drawing in fluid from the inlet port during the suction stroke and then pressurizing and expelling it to the outlet port during the discharge stroke.The variable displacement capability is achieved by physically changing the swashplate's angle;a greater angle results in a longer piston stroke and a higher displacement per revolution,and vice versa.

The designation"DFR1"in the model number signifies that this unit is equipped with a sophisticated pressure and flow control regulator.This integrated control system automatically adjusts the pump's displacement to maintain a pre-set system pressure(pressure compensation function)and can also limit the output flow based on the pressure drop across a load-sensing orifice(flow control function).This dual functionality allows the pump to provide only the flow and pressure required by the system at any given moment,leading to significant energy savings and reduced heat generation.

3.Distinguishing Features and Component Architecture

Advanced Control and Regulation System

The DFR1 control mechanism is a defining feature of this hydraulic piston pump.It enables the pump to operate in a"load-sensing"mode,where the output is precisely matched to the instantaneous demands of the application.This eliminates the wasteful energy losses typically associated with fixed-displacement pumps and flow-control valves,where excess flow is dumped over a relief valve.The control response time is notably short,ensuring system stability and precise actuator control during dynamic operation.

Robust Construction and Material Selection

The pump is built for longevity in harsh environments.The use of a high-strength cast iron housing provides excellent resistance to mechanical stress and corrosion.Internally,critical components like the cylinder block and pistons are manufactured from hardened steels to withstand high cyclic pressures.The rotating group is designed for optimal lubrication,and the hydrostatically balanced bearings contribute to a long operational life,even under continuous high-pressure operation.

Versatile Installation and Configuration Options

The A10VSO 28 DFR1/31R-VPA12N00 conforms to international standards,featuring ISO mounting flanges and SAE metric port connections for seamless integration into global machine designs.It also offers a"through-drive"capability,denoted by specific codes in its model suffix.This allows for the piggyback mounting of additional pumps,such as gear or vane pumps,onto the same driveshaft to create a compact,multi-circuit hydraulic power source.

4.Primary Application Areas and Industry-Specific Solutions

This axial piston variable pump finds extensive use in a diverse range of sectors due to its efficiency and versatility.In industrial machinery,it is a cornerstone for plastic injection molding machines,metal forming presses,and machine tools,where its precise pressure and flow control are essential for product quality and cycle times.

The mobile machinery sector,including construction equipment like excavators and loaders,relies on this pump for its robust performance and energy-saving load-sensing capability,which directly translates to lower fuel consumption.Furthermore,it is employed in material handling systems such as conveyor drives and forestry equipment,where its reliability and ability to handle variable loads are highly valued.

5.Operational Advantages and Economic Value Proposition

Superior Energy Efficiency and Heat Management

The most significant advantage of this variable displacement pump is its potential for substantial energy savings.By matching output to demand,it minimizes the losses associated with traditional throttling control methods.This"on-demand"operation not only reduces power consumption from the prime mover but also drastically cuts down on heat generation within the hydraulic fluid.Lower operating temperatures reduce the stress on all hydraulic components and can extend the service life of the entire system,while also reducing the need for large and expensive cooling systems.

Enhanced System Performance and Reliability

The pump contributes to a more responsive and stable hydraulic system.The low noise design improves the working environment and is often a requirement for machinery operating in noise-sensitive areas.Its high volumetric and overall mechanical efficiency ensure that maximum power is transferred from the engine or motor to the hydraulic actuators.The robust design,coupled with the requirement for clean oil,leads to high mean time between failures(MTBF),minimizing unplanned downtime and reducing the total cost of ownership.

Frequently Asked Questions(FAQs)

1.How does the DFR1 control mechanism actually save energy?

The DFR1 control combines pressure compensation and load-sensing flow control.In simple terms,the pump constantly monitors the system's pressure requirement and only produces enough pressure to overcome the highest load,plus a small margin.Simultaneously,it provides only the flow needed by the actuators.This is in stark contrast to a fixed displacement pump,which produces maximum flow whenever it is running,with excess flow being converted into heat by being dumped over a relief valve.By eliminating this wasteful throttling,the DFR1-controlled pump significantly reduces energy input and cooling requirements.

2.What is the practical implication of the"through-drive"capability?

The"through-drive"or"through-shaft"feature allows the primary pump to drive one or more secondary pumps from its rear shaft extension.This enables the creation of a multi-circuit hydraulic system from a single prime mover(like an electric motor or engine).For example,one circuit could be dedicated to the main propulsion of a machine using this A10VSO pump,while a secondary gear pump mounted on the through-drive could power auxiliary functions like steering or cooling fans.This saves space,simplifies the drivetrain,and reduces costs compared to using multiple independent pump and motor sets.

3.Can this pump be used with environmentally friendly or fire-resistant hydraulic fluids?

Yes,while the pump's published performance data is typically based on mineral oil,it is compatible with other fluid types,including environmentally acceptable fluids(EALs)and fire-resistant fluids(HFDU,HFA,etc.).However,it is crucial to consult the manufacturer's documentation or a Rexroth application engineer when switching fluids.Using non-mineral oils may require adjustments to operating parameters,as they can have different viscosity profiles and lubricating properties,which might affect maximum pressure ratings,speed limits,and seal compatibility.

4.What are the critical maintenance practices for ensuring a long service life for this pump?

The single most important maintenance practice is maintaining exceptional fluid cleanliness.Contamination is the leading cause of failure in high-pressure piston pumps.Regularly monitoring and replacing hydraulic filters is paramount.Additionally,ensuring that the inlet pressure(suction pressure)remains within the specified limits is critical to prevent cavitation,which can cause severe damage to the piston and swashplate surfaces.Periodically checking for external leaks,unusual noises,or elevated temperatures can help identify potential issues before they lead to catastrophic failure.

5.How does this axial piston pump differ from a vane or gear pump in terms of performance?

While gear and vane pumps are known for their simplicity and cost-effectiveness,this axial piston pump offers superior performance in several key areas.It operates at much higher pressures(280-350 bar continuous)compared to most vane and gear pumps.It also offers significantly higher volumetric and overall efficiency,leading to lower energy consumption.The key differentiator is the variable displacement capability with sophisticated electronic or hydraulic control,which gear and vane pumps typically lack.This makes the axial piston pump the preferred choice for high-power,high-efficiency,and dynamically controlled systems.