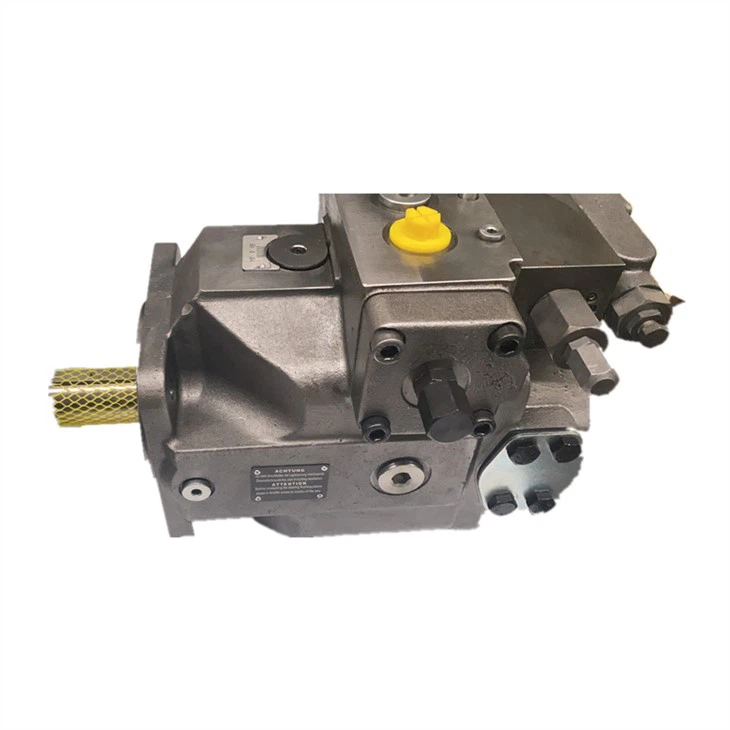

The Rexroth A4VSO250DR stands as a premier example of advanced hydraulic pump engineering,specifically designed as a variable displacement piston pump for high-power,closed-loop systems.This Rexroth hydraulic pump utilizes a swashplate design to deliver precise fluid power in demanding industrial environments.With a maximum displacement of 250 cm³/rev and capability to handle continuous operating pressures up to 35 MPa(with peak pressures reaching 40 MPa),this pump is engineered for reliability and efficiency in severe applications.The A4VSO series represents the culmination of Rexroth's expertise in hydraulic technology,offering exceptional control responsiveness,minimal noise generation,and robust construction that ensures extended service life even in the most challenging operating conditions found in metal processing,heavy construction,and marine industries.

1 Product Overview and Technology Foundation

The Rexroth A4VSO250DR exemplifies sophisticated hydraulic engineering through its axial piston pump design with variable displacement capabilities.This pump operates on the swashplate principle where multiple pistons are arranged axially in a cylinder block,and their reciprocating motion is controlled by the angle of a swashplate.As the drive shaft rotates the cylinder block,the pistons move in and out of their bores,creating the pumping action that moves hydraulic fluid from the inlet to the outlet port.The variable displacement functionality is achieved by adjusting the swashplate angle,which directly changes the piston stroke length and consequently the pump's displacement volume per revolution.

This specific variable displacement piston pump is configured for closed-loop systems,particularly in applications requiring precise control over hydraulic motors.The A4VSO250DR designation indicates a specific pump series with 250 cm³/rev maximum displacement,with the"DR"suffix typically referring to its control type and configuration.What sets this Rexroth hydraulic pump apart is its exceptional volumetric and mechanical efficiency,which remains consistently high across its entire operating range.The pump incorporates advanced features like pre-compression panels in the valve plate to minimize fluid compression losses and noise generation,making it suitable for noise-sensitive environments while maintaining operational efficiency.

2 Technical Specifications and Performance Characteristics

The performance profile of the Rexroth A4VSO250DR is defined by several critical technical parameters that establish its operational boundaries and capabilities.The pump delivers a maximum displacement of 250 cm³per revolution,enabling substantial flow output at standard industrial drive speeds.With a maximum rated speed of 1500 rpm,the pump can generate theoretical flow rates up to 375 L/min under optimal conditions,making it suitable for high-power hydraulic systems requiring significant fluid movement.

This variable displacement piston pump operates effectively within a comprehensive pressure spectrum,with a nominal continuous pressure rating of 35 MPa and the ability to withstand peak pressures up to 40 MPa for intermittent duty cycles.The pump's inlet section requires a minimum absolute pressure of 0.08 MPa to prevent cavitation,with a maximum allowable inlet pressure of 3 MPa.Case drain pressure is limited to 0.4 MPa maximum,ensuring proper lubrication and cooling without overstressing internal seals and components.The pump demonstrates power transmission capabilities exceeding 200 kW at maximum displacement and pressure parameters,with torque ratings reaching approximately 1391 Nm at 35 MPa pressure differential.

3 Design Features and Component Excellence

The A4VSO250DR incorporates multiple advanced engineering features that contribute to its reliability and performance.The pump employs hydrostatically balanced slippers that reduce wear and extend component life by maintaining optimal oil film thickness between contact surfaces.These slippers are designed with pressure pockets that create a balancing hydraulic force,ensuring smooth operation even at maximum pressure conditions.The valve plate geometry is optimized for minimal flow pulsation and pressure peaks,resulting in quieter operation and reduced system vibration compared to conventional designs.

The construction quality of this Rexroth hydraulic pump is evident in its material selection and component manufacturing.Critical parts like the cylinder block,pistons,and swashplate are manufactured from high-grade steels with specialized surface treatments to enhance wear resistance and durability.The pump incorporates large-size bearings specifically selected to handle substantial radial and axial loads,contributing to the pump's ability to maintain precise internal clearances over extended operating periods.The housing design provides structural rigidity while facilitating efficient heat dissipation,helping to maintain optimal operating temperatures across various duty cycles.

4 Control Options and Functional Versatility

The A4VSO250DR variable displacement piston pump offers multiple control possibilities to match specific system requirements.The standard configuration typically includes pressure compensator control,which automatically adjusts pump displacement to maintain a preset system pressure,effectively reducing energy consumption during standby or low-demand conditions.For applications requiring more sophisticated functionality,the pump can be equipped with load-sensing controls that modulate output based on actual system demand,or with electro-proportional controls that enable remote adjustment of pump parameters through electrical signals.

This Rexroth hydraulic pump demonstrates particular excellence in its zero-position control characteristics,which is especially valuable in closed-loop hydrostatic transmission systems.The pump's design effectively addresses common tray phenomena that often occur when variable pumps cross the zero displacement point,ensuring smooth direction changes without pressure spikes or flow instabilities.For applications requiring precise displacement feedback,the pump can be equipped with position sensors that provide accurate swashplate angle information to the system controller,enabling precise flow control regardless of load conditions.

5 Primary Applications and Industrial Solutions

The A4VSO250DR finds extensive application across various heavy industries where high-power hydraulic systems are essential.In metal forming and processing equipment,this pump provides the precise pressure and flow control necessary for operations like extrusion,forging,and stamping,where consistent force application is critical to product quality.The pump's robust pressure capabilities and precise control make it ideal for these demanding applications,with the 35 MPa continuous pressure rating providing substantial force generation in compact machine designs.

The marine industry utilizes this variable displacement piston pump in steering gears,winch drives,and other specialized hydraulic systems where reliability and compact power density are essential.The pump's ability to maintain precise control under varying load conditions makes it particularly valuable in dynamic positioning systems and thrusters where responsive hydraulic power is mandatory.Additionally,the pump's configuration options make it suitable for plastic injection molding machinery,where consistent and repeatable hydraulic performance directly impacts production quality and cycle times.

6 Operational Advantages and Economic Benefits

The A4VSO250DR delivers significant operational advantages through its advanced design and engineering.The pump demonstrates exceptional energy efficiency across its operating range,maintaining high volumetric efficiency(typically above 95%)and mechanical efficiency(often exceeding 90%)at rated conditions.This efficiency translates directly to reduced energy consumption,particularly in applications with variable flow requirements where the pump can reduce displacement to match actual system demand rather than relying on throttling or bypass losses.

The economic benefits of this Rexroth hydraulic pump extend beyond energy savings to include reduced total cost of ownership through extended service intervals and enhanced reliability.The pump's robust construction and optimized hydraulic balancing contribute to extended component life,particularly in the critical wear parts like pistons,slippers,and bearings.The design incorporates service-friendly features that simplify maintenance and reduce downtime,with readily accessible filtration points and clear visual indicators for routine inspection.When maintenance is required,the modular construction and standardized components help minimize repair time and costs,ensuring maximum equipment availability.

7 Implementation and System Integration Guidance

Proper implementation of the A4VSO250DR requires careful attention to system design and installation parameters.The pump must be mounted securely to a stable foundation with proper alignment to the drive source,using recommended coupling types to minimize radial and axial loads on the pump shaft.Installation should include appropriate isolation elements in all connecting pipelines to reduce noise transmission and prevent vibration-related failures.The reservoir design must ensure adequate fluid conditioning,with filtration recommendations typically targeting ISO 4406 18/16/13 or better cleanliness levels to protect the pump's precision components.

For applications involving vertical mounting orientation,the A4VSO250DR requires specific attention to bearing lubrication.In such configurations,the pump must be equipped with a dedicated flushing connection(typically at port U)that provides a continuous flow of clean,cool oil to the front bearing and shaft seal area.This flushing flow,which requires approximately 12 L/min for the 250 cm³/rev size,merges with the case drain flow and returns to the reservoir,ensuring adequate lubrication and heat removal from these critical areas.System designers should incorporate appropriate heat exchangers when continuous operation at maximum pressure is anticipated,maintaining optimal fluid temperature between 30°C and 60°C for maximum component life and performance.

Frequently Asked Questions(FAQs)

What specific maintenance practices maximize the service life of the A4VSO250DR variable displacement piston pump?

Maintaining strict fluid cleanliness standards represents the most critical maintenance practice for maximizing pump longevity.Regular monitoring and replacement of hydraulic filters is essential,with recommended cleanliness targets typically at ISO 4406 18/16/13 or better.Periodic fluid analysis helps detect early signs of contamination or component wear before they lead to catastrophic failures.Additionally,monitoring operating temperatures and ensuring adequate cooling prevents premature degradation of seals and fluid properties,while regular inspection of drive couplings and shaft seals prevents contamination ingress.

How does the A4VSO250DR's design specifically benefit closed-loop hydrostatic transmission systems?

This Rexroth hydraulic pump incorporates design features specifically optimized for closed-loop applications,including specialized pre-compression zones in the valve plate that ensure smooth pressure transitions during direction changes.The pump demonstrates exceptional zero-position control stability,effectively eliminating the tray phenomenon common in many axial piston pumps when crossing the zero displacement point.This capability ensures smooth direction changes in hydrostatic drives without the pressure spikes or flow instabilities that can cause jerky operation or component stress.

What are the key considerations when selecting between pressure compensator,load-sensing,and electro-proportional controls for this pump?

The control selection depends primarily on the specific energy efficiency and functional requirements of the application.Pressure compensator controls offer simplicity and reliable pressure limitation,making them ideal for systems with intermittent operation.Load-sensing controls provide superior energy efficiency for applications with varying flow demands,as the pump only produces the flow and pressure required by the actuators.Electro-proportional controls offer the highest level of integration with electronic control systems,enabling programmable operation and advanced system optimization strategies.

Can the A4VSO250DR operate effectively with environmentally acceptable fluids such as water-glycol or synthetic esters?

While primarily designed for mineral-based hydraulic oils,this variable displacement piston pump can be adapted for use with certain HF fluids through specific configuration options.Applications involving water-glycol fluids(HFC)may require special materials for compatibility and reduced performance parameters due to the different lubrication properties and viscosity characteristics of these fluids.For synthetic esters(HEES)and other environmentally adaptive fluids,consultation with Rexroth technical support is recommended to ensure proper material compatibility and potential adjustment of operating parameters.

What diagnostic indicators should operators monitor to identify potential issues with this pump before catastrophic failure occurs?

Key diagnostic indicators include unusual noise patterns,particularly during specific operating conditions like startup or pressure transitions,which can signal cavitation or internal wear.Monitoring case drain flow provides valuable insights into the pump's internal condition,with gradually increasing drain flow indicating wear in the rotating group.Additionally,changes in response time or stability of the control system can signal issues with the control piston or contamination in the control circuit,while elevated operating temperatures often indicate developing problems with internal clearances or lubrication.