Explore the convergence of digital hydraulics,AI,and IoT in modern industrial systems.Discover how smart hydraulics boost efficiency,slash energy use,and enable predictive maintenance.

Introduction:The New Era of Fluid Power

For decades,hydraulic systems have been the backbone of heavy-duty industrial applications,from construction machinery to metal processing.Yet,traditional hydraulics faced criticism for inefficiency,noise,and high maintenance costs.Today,a transformative wave is sweeping the sector:digitalization,automation,and intelligent technologies are merging to create smarter,greener,and more connected fluid power systems.This article delves into the core trends driving this shift—digital hydraulic components,AI-driven optimization,and electrification—and their real-world impact on industries worldwide.

1.Digital Hydraulics:Precision,Efficiency,and Connectivity

Digital hydraulic components are replacing analog systems,enabling granular control over pressure,flow,and motion.Key innovations include:

Digital Valves and Motors:Companies like Haiteke and Suzhou Liyuan have launched digital valves and motors with sub-micron dynamic compensation and adaptive algorithms.These achieve flow control accuracy of 0.1%and operate at over 98%efficiency in extreme temperatures(-40°C to 120°C),outperforming legacy systems.

Integrated Controllers:Zhejiang University’s real-time digital controllers synchronize multi-device operations within 100 milliseconds,critical for complex tasks in CNC machining and robotics.

IO-Link and Bluetooth Interfaces:Bosch Rexroth’s proportional valves now support wireless connectivity,allowing parameter adjustments via apps and seamless integration into IoT ecosystems.

2.AI and Digital Twins:From Reactive to Predictive Systems

Artificial intelligence and digital twins are revolutionizing hydraulic design,monitoring,and maintenance:

Predictive Maintenance:AI models analyze sensor data(e.g.,pressure,temperature)to forecast failures.For example,Bosch Rexroth’s Hydraulic Hub platform uses AI to troubleshoot components,reducing unplanned downtime by 30%.

Energy Optimization:Digital twins simulate system behavior to identify energy waste.In metallurgy,AI-driven hydraulic systems have cut energy consumption by 40–60%in applications like steel rolling mills.

Autonomous Control:Researchers at ICFP 2025 highlighted AI-based controllers that self-adjust to load changes,enabling"set-and-forget"operations in mobile machinery.

3.Electrification and Hybridization:Green Power Meets High Density

The fusion of electric drives with hydraulics is resolving the trade-off between power density and sustainability:

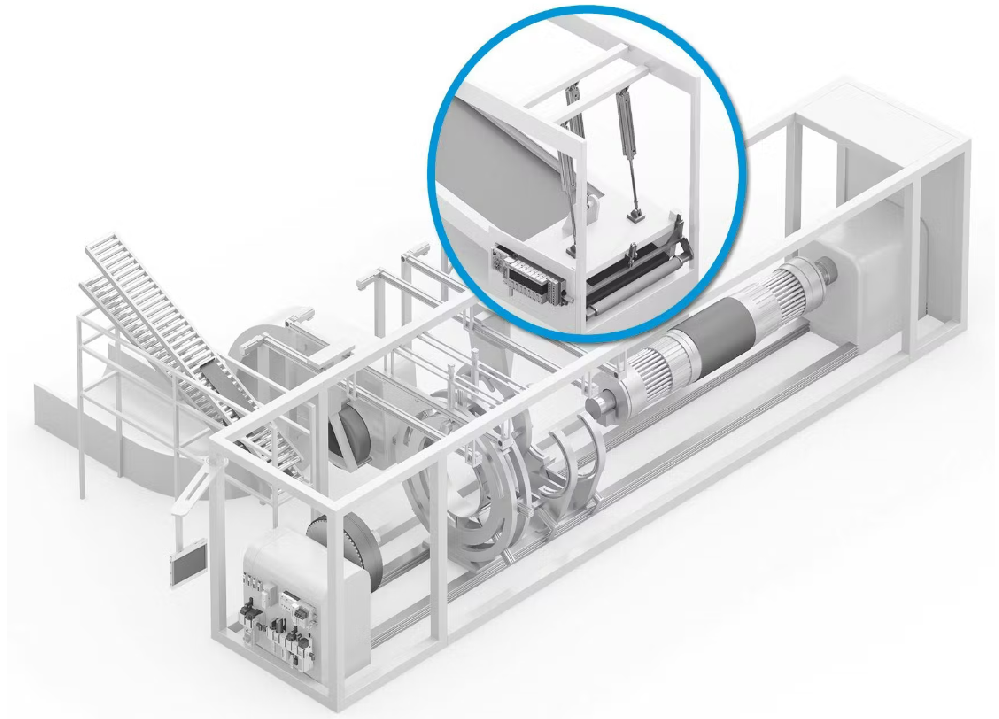

Variable-Speed Pump Drives:Systems like Bosch Rexroth’s CytroPac use servo-driven pumps to match output to demand,slashing energy use by 50%compared to constant-speed systems.

Electro-Hydraulic Actuators(EHAs):These compact units combine electric motors with hydraulic cylinders,eliminating leakage and reducing noise.In injection molding machines,EHAs have lowered energy costs by 60%.

Regenerative Energy Recovery:Heavy-lift applications,such as cranes and presses,now reuse gravitational energy via hydraulic accumulator arrays,achieving 70%energy recycling rates.

4.Smart Integration:The IoT and Modular Automation

Interconnectivity and modular designs are streamlining hydraulic system deployment:

IO-Link Networks:Festo’s digital pneumatics and Emerson’s smart sensors use IO-Link to transmit real-time diagnostics,simplifying troubleshooting.

Plug-and-Play Hydraulics:Bosch Rexroth’s modular CytroPac power units allow quick configuration for diverse pressures and flows,cutting installation time by 50%.

Cloud Platforms:NFPA’s digital fluid power frameworks enable remote monitoring of hydraulic health metrics,from pump wear to fluid contamination.

5.Industry 4.0 Applications:Case Studies of Transformation

Smart hydraulics are already delivering value across sectors:

Construction Machinery:Sany’s digital cylinders with visual encoding achieve 0.01 mm motion precision,enabling autonomous grade control in excavators.

Metallurgy:Zhongye Group’s servo-hydraulic systems in steel plants reduce tonnage energy use by 1.5 kWh per ton of steel,saving 60,000 tons of coal annually.

Mobile Machinery:Husco’s electro-hydraulic valves enable GNSS-guided automation in agricultural equipment,boosting field efficiency by 25%.

Challenges and Future Directions

Despite progress,barriers remain:

Data Security:As hydraulics connect to cloud platforms,vulnerabilities to cyberattacks require robust encryption,as seen in Bosch Rexroth’s CRA-compliant ctrlX OS.

Cost of Retrofitting:Small manufacturers often struggle to upgrade legacy systems.Modular retrofits(e.g.,Danfoss’PVG valve upgrades)offer a middle ground.

Skill Gaps:AI-augmented tools like Hydraulic Hub are bridging this gap by guiding technicians through complex repairs.

The future will see quantum-inspired optimization and self-healing hydraulics,but immediate gains will come from scaling today’s digital solutions.

Conclusion:The Path to Autonomous Hydraulics

The hydraulic industry’s transformation is no longer about incremental improvements—it’s a fundamental shift toward autonomous,efficient,and sustainable fluid power.By embracing digital components,AI,and electrification,manufacturers can unlock unprecedented productivity while meeting ESG goals.As Bosch Rexroth’s Steffen Haack noted,“The future belongs to systems that learn,adapt,and communicate.”For industries ready to innovate,intelligent hydraulics will be the engine of competitive advantage.

References

Hunan Provincial Government:"Digital Hydraulic Valve and Motor Breakthroughs"(2025).

POWER&MOTION:"Automation’s Impact on Hydraulic and Pneumatic Design"(2025).

Bosch Rexroth:"Hydraulic Hub and Digital Services at Hannover Messe 2025".

ICFP 2025:"AI and Digital Twin Applications in Fluid Power".

Bosch Rexroth:"CytroPac and EMO Hannover Showcase".

Wang Chengxiang,Bosch Rexroth:"Industrial Hydraulic Trends"(2025).

NFPA:"Digital Fluid Power for Industrial Automation"(2025).

CSM:"Servo-Driven Smart Hydraulics in Metallurgy"(2025).