Synchronous control solution for the hydraulic system of steel plant cooling beds - Based on the application of CASAPPA HDD35 series flow diverters

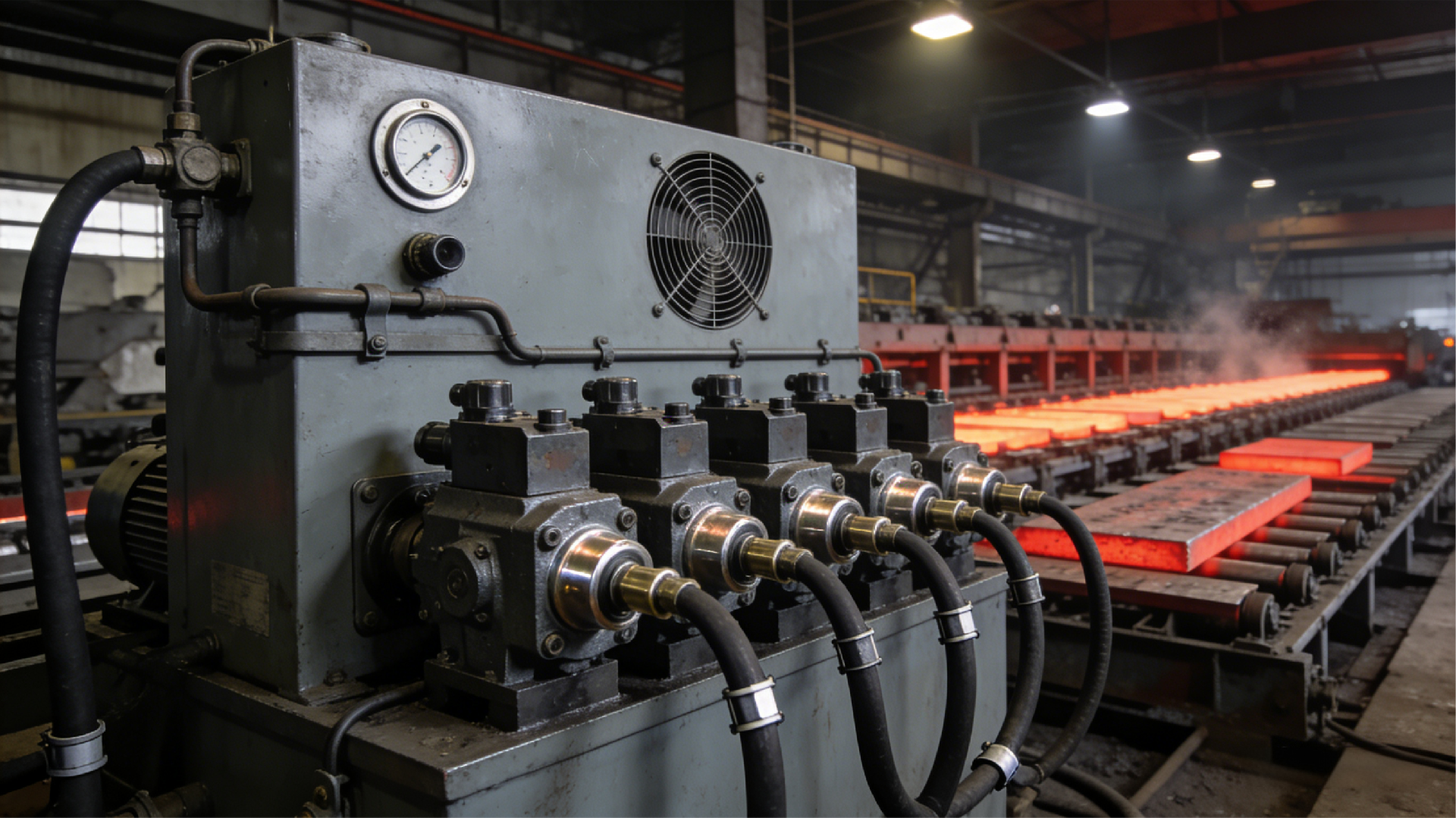

In the metallurgical and casting industry, the cooling bed, as the core equipment for cooling, straightening and conveying steel after rolling, its operational stability directly affects the quality of steel products and production efficiency. The synchronous drive requirement for the cooling bed is extremely high. It is necessary to precisely control the coordinated action of multiple oil cylinders through the hydraulic system to ensure that the steel is evenly stressed and smoothly conveyed during the cooling process. This article focuses on the synchronous control technology of the hydraulic system of the cooling bed, and elaborates on the solution of achieving the synchronous operation of 8 hydraulic cylinders by using the CASAPPA cast iron HDD35 series flow distributor, highlighting its outstanding advantages in synchronous performance and equipment reliability.

1. Core Design of the Hydraulic System: The flow divider serves as the synchronous control core

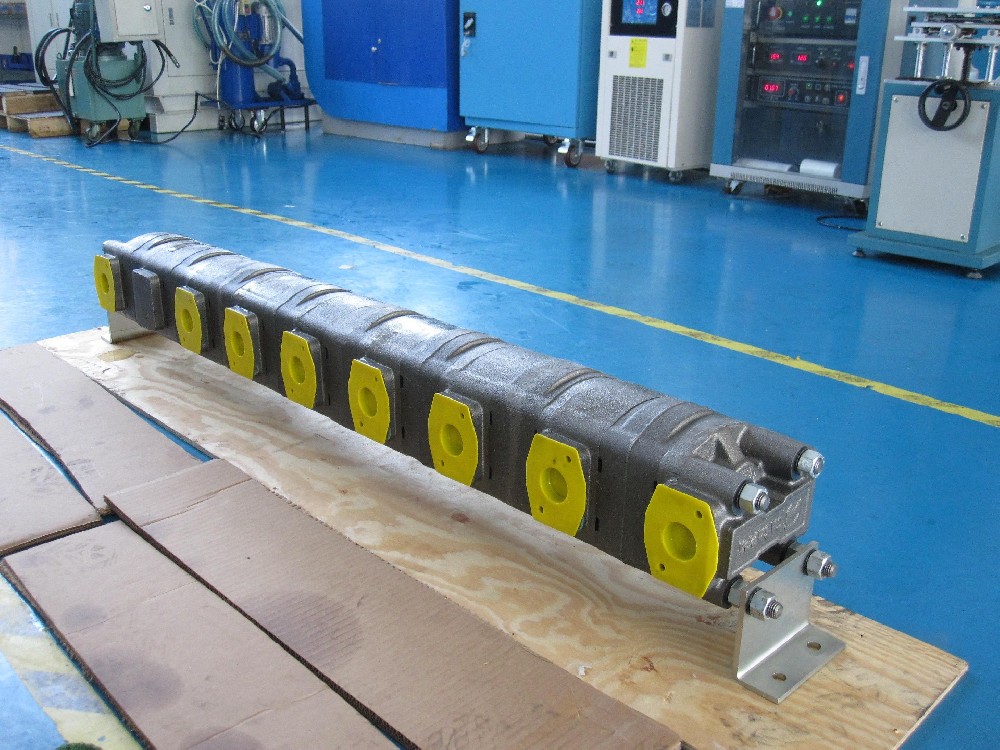

The core demand of the hydraulic system of the cooling bed is to achieve high-precision synchronous operation of multiple cylinders, and the uniformity of flow distribution is the key to synchronous control. In this scheme, the hydraulic station adopts an architecture of "single hydraulic source + flow divider + multiple actuating cylinders", among which the CASAPPA HDD35 series cast iron flow divider serves as the core control component, undertaking the key task of precisely distributing hydraulic oil to the 8 hydraulic cylinders.

As a globally renowned manufacturer of hydraulic components, CASAPPA's HDD35 series flow diverters are specially designed for heavy-duty and high-precision synchronous scenarios. They are cast from high-strength cast iron, featuring excellent compressive resistance and wear resistance, and can adapt to the harsh working conditions of steel mills, such as high temperatures, much dust, and frequent vibrations. This series of products achieves even flow distribution through an internal precise gear structure. It can precisely distribute the high-pressure oil output by the hydraulic station to 8 branches in a preset proportion, ensuring that each cylinder receives the same flow supply and laying the foundation for synchronous operation from the source.

2. Core advantages of synchronous operation: Enhance the operational accuracy and stability of the cooling bed

The CASAPPA HDD35 series flow diverter is adopted to achieve the synchronous operation of 8 hydraulic cylinders, bringing multiple core advantages to the steel plant's cooling bed, which are specifically reflected in the following aspects:

Ultra-high synchronization accuracy ensures steel quality: The precise gear structure of the flow divider can achieve a flow distribution error within ±2%, ensuring that the extension and retraction speeds and strokes of the 8 cylinders are exactly the same. This enables the components of the cooling bed, such as the material support plates and conveyor chains, to move synchronously, preventing the steel from shifting, deforming or getting surface scratches during the cooling process, significantly improving the dimensional accuracy and surface quality of products like profiles and plates.

Load balancing, extending equipment life: Under synchronous operation, the 8 cylinders evenly share the weight load of the cooling bed and steel, avoiding faults such as seal damage and piston rod bending caused by overloading of a single cylinder. Meanwhile, the CASAPPA cast iron distributor has excellent impact resistance and can adapt to the load fluctuations during the start-up and shutdown of the cooling bed, effectively extending the service life of core components such as hydraulic cylinders and distributors, and reducing equipment maintenance costs.

Simplify system design and enhance operational reliability: Compared with the synchronous scheme that uses complex control components such as electro-hydraulic servo valves and proportional valves, the mechanical structure of the flow divider is simpler and does not require complex electronic control modules and debugging processes. Its "ready-to-use" feature simplifies the pipeline layout and control logic of the hydraulic system, reduces electrical failure points, enhances the operational reliability of the system under harsh working conditions in steel mills, and lowers the equipment downtime rate.

3. Outstanding performance of the equipment: Meeting the strict demands of the metallurgical industry

The CASAPPA HDD35 series flow diverter not only performs exceptionally well in synchronous control, but its overall performance also fully meets the strict operational requirements of steel plant cooling beds

Strong flow adaptability: This series of diverters support a single-channel flow adjustment range of 50-250 L/min. They can flexibly match the output flow of the hydraulic station according to the operating speed requirements of the cooling bed, meeting the cooling and transportation needs of steel of different specifications.

High pressure resistance grade: The rated working pressure can reach 31.5 MPa, capable of withstanding the high-pressure impact during heavy-load operation of the cooling bed, ensuring stable output of the hydraulic system under high loads.

Strong anti-pollution ability: The cast iron material shell and the internal precision gears have undergone special surface treatment, providing excellent anti-wear and anti-pollution capabilities. They can adapt to the working conditions with a small amount of impurities in the hydraulic oil of steel mills, reducing equipment failures caused by oil contamination.

Convenient installation and maintenance: The diverter adopts a modular design, which is compact in size and light in weight, making it easy to install and layout in the narrow space of the hydraulic station of the cold bed. Meanwhile, its mechanical structure has an extremely low failure rate. Daily maintenance only requires regular checks on the cleanliness of the oil and the sealing of the connecting pipelines, reducing the maintenance workload.

Conclusion

In the hydraulic system of the steel plant's cooling bed, the CASAPPA HDD35 series cast iron flow distributor is adopted to achieve the synchronous operation of 8 hydraulic cylinders, which is the optimal solution that takes into account control accuracy, operational stability and cost-effectiveness. This solution, through the high-performance performance of core components, not only resolves the technical challenges of multi-cylinder synchronous drive, but also helps metallurgical enterprises improve product quality, reduce production costs, and enhance production continuity, providing reliable technical support for the efficient and green development of the metallurgical casting industry. With the continuous upgrading of metallurgical technology, the application of CASAPPA flow dividers in cooling beds and other synchronous drive equipment will become more widespread, empowering the upgrading of industry equipment.