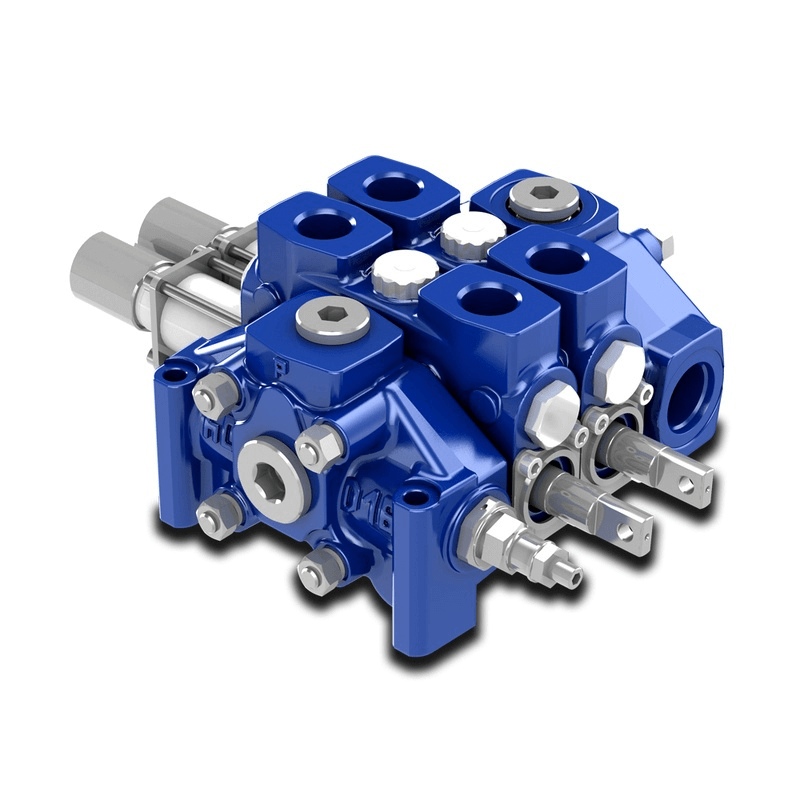

The Hydrocontrol HC-D16/1 is a heavy-duty hydraulic valve engineered to deliver reliable performance in the most challenging operating environments.As a hydraulic directional control valve,its primary function is to precisely direct the flow of hydraulic fluid to various actuators,such as cylinders and motors,in mobile machinery.With a rated flow of 160 L/min and a maximum operating pressure of 350 bar,this monoblock,single-spool valve is a fundamental component for controlling auxiliary functions in equipment like drill rigs,compact construction machinery,and specialized engineering vehicles.Its design prioritizes durability,straightforward integration,and versatile control options to meet the rigorous demands of off-highway applications.

1.Product Overview&Brand Positioning

Hydrocontrol,an Italian company with a heritage dating back to 1969,has established itself as a specialist in the design and manufacture of hydraulic systems for mobile machinery.The company focuses on providing comprehensive"hydraulic control systems"for sectors including construction,earthmoving,and material handling.

The HC-D16 series,to which the HC-D16/1 belongs,is a well-regarded product line known for its modularity and robustness—often specified for loaders,excavators,and drill rigs.The HC-D16/1 model embodies this reputation,offering a compact and self-contained solution for single-function control.

2.Detailed Technical Specifications

The HC-D16/1 is characterized by its straightforward and robust technical profile,designed for easy integration and long service life.

2.1 Technical Data Table

Parameter

Specification

Valve Type Monoblock,Single-Spool Directional Control Valve

Model Code HC-D16/1

Rated Pressure 350 bar

Rated Flow 160 L/min

Maximum Flow 200 L/min

Control Type Manual(Lever Control)

Center Position Configuration O-type(W001A spool type)

Port Connections P,A,B:G3/4"(ISO 228/1);T:G1"

Bridge Function Optional(Allows oil passage to downstream components in neutral)

3.Core Features&Functional Analysis

3.1 Monoblock Construction for Leak Resistance

Unlike modular,sectional valves,the HC-D16/1 is a single,solid cast unit.This monoblock design significantly reduces the number of potential external leakage points,enhancing the valve's reliability and reducing maintenance needs in dirty and high-vibration environments typical of mobile equipment.

3.2 Heavy-Duty Pressure and Flow Ratings

The valve's 350 bar pressure rating and 160 L/min flow capacity classify it as a heavy-duty hydraulic valve.This ensures it can handle the high-power hydraulic requirements of industrial machinery without becoming a system bottleneck,providing ample capacity for demanding actuators.

3.3 Manual Lever Control and Spool Options

The standard configuration includes a manual lever control(H001)for direct and intuitive operator command.The valve utilizes a W001A spool type,which features an O-type center position that blocks all ports(P,T,A,B)in the neutral state—effectively locking the actuator in place.

3.4 Optional Bridge Function for System Flexibility

A key feature is the availability of a"bridge"function.When specified,this allows hydraulic oil to pass through the valve's neutral position,enabling it to supply power to other hydraulic components(e.g.,another valve bank)in a series circuit.This is crucial for designing multi-function hydraulic systems without the need for complex external porting.

4.Performance Advantages&Application-Specific Value

The design of the HC-D16/1 translates into several key benefits for equipment manufacturers and end-users:

Superior Reliability in Harsh Conditions:The combination of a monoblock body and high-pressure capability makes this valve exceptionally robust.It is built to withstand the pressure spikes,contamination,and mechanical shocks common in applications like mining,drilling,and construction—maximizing machine uptime.

Simplified System Design and Integration:The availability of standard and optional features(like the bridge function)allows system designers to simplify the overall hydraulic circuit.The standardized porting and compact design also make it easier to fit the valve into space-constrained equipment.

Low Internal Leakage for Precise Control:The precision machining of the spool and bore,combined with the O-type center configuration,ensures minimal internal oil leakage in the neutral position.This provides better load holding for suspended loads and more precise control over the connected actuator.

5.Expanded Perspective:Directional Valves in Mobile Hydraulics

Understanding the broader context of hydraulic valve types and selection criteria is essential for optimizing system design.

5.1 Valve Architecture:Monoblock vs.Sectional Valves

The HC-D16/1 represents one of two primary architectural philosophies in directional control valve design:

Monoblock Valves(Like HC-D16/1)

Construction:Single piece of metal(cast unit).

Advantages:Inherently leak-resistant,compact,and reliable—ideal for fixed-function applications.

Limitations:Less flexibility;adding a function requires a completely new valve.

Sectional Valves(Other HC-D16 Series Models)

Construction:Multiple individual sections bolted together.

Advantages:High customizability(2–10 sections in HC-D16 series);mixed spool types per assembly.

Limitations:More potential leakage points at section interfaces.

Selection Insight:The monoblock HC-D16/1 is optimal for dedicated,single-function circuits where robustness is critical.A sectional HC-D16 valve suits machines needing multi-function control with customization.

5.2 Application Scenarios&Industry Fit

The HC-D16/1 is engineered for specific mobile equipment use cases:

Auxiliary Circuit Control in Drill Rigs:Controls outriggers,stabilizers,or tool changers—where reliable load holding is critical.

Compact Construction&Material Handling:Fits small loaders,trenchers,and manipulator arms—matching single primary work function needs and tight space constraints.

Municipal&Special Vehicles:Used in sweepers,refuse trucks,and wreckers—controlling high-importance functions like packing blades or lifts.

5.3 Critical Implementation&Selection Guide

Successfully implementing the HC-D16/1 requires attention to key details:

Spool Type Matching:The standard O-type(W001A)is for load holding.Verify if other spool types(e.g.,Y-type for motors)are available to match actuator needs.

Porting Compatibility:Ensure G-series threaded ports(P/A/B:G3/4",T:G1")align with system hoses and fittings.Specify the bridge function at order if needed for series circuits.

Control Mechanism Check:Confirm with Hydrocontrol or distributors if alternative controls(hydraulic pilot/electric actuation)are available for this model—matching the machine’s operational interface.

6.Frequently Asked Questions(FAQs)

1.What is the main advantage of the monoblock design in the HC-D16/1?

The primary advantage is enhanced reliability and leak resistance.Being a single casting eliminates internal leakage paths that exist between sectional valve sections,making it more robust and less maintenance-prone in harsh,high-vibration environments(e.g.,construction,mining).

2.Can this valve be used to control a hydraulic motor?

While technically possible,the standard O-type spool(W001A)is not ideal.Its closed center blocks all ports in neutral,trapping oil and risking motor damage if coasting occurs.For motor control,a spool with Y-type or P-type center conditions is needed—consult a Hydrocontrol specialist to confirm spool availability for this model.

3.What does the"bridge function"option do?

When specified,the bridge function lets pump oil(from P port)flow through the valve in neutral to supply other downstream valves.This eliminates complex external plumbing(manifolds,hoses)for daisy-chaining valves,simplifying system design.

4.Is the HC-D16/1 suitable for open-center or closed-center pump systems?

The standard HC-D16/1(O-type spool)is designed for fixed-displacement pumps in open-center systems—oil flows from P to T in neutral.It is not typically used with variable-displacement(closed-center)pumps,as blocked neutral ports would cause pressure spikes.Verify system compatibility during design.

5.How does this valve compare to a proportional valve for actuator speed control?

The HC-D16/1(manual lever)is an on/off valve,directing full or no flow to the actuator—speed is controlled by lever movement,not precise modulation.Proportional valves vary flow via electrical signals for finer speed control.The HC-D16/1 is chosen for reliability and cost-effectiveness where precise speed modulation is unnecessary.