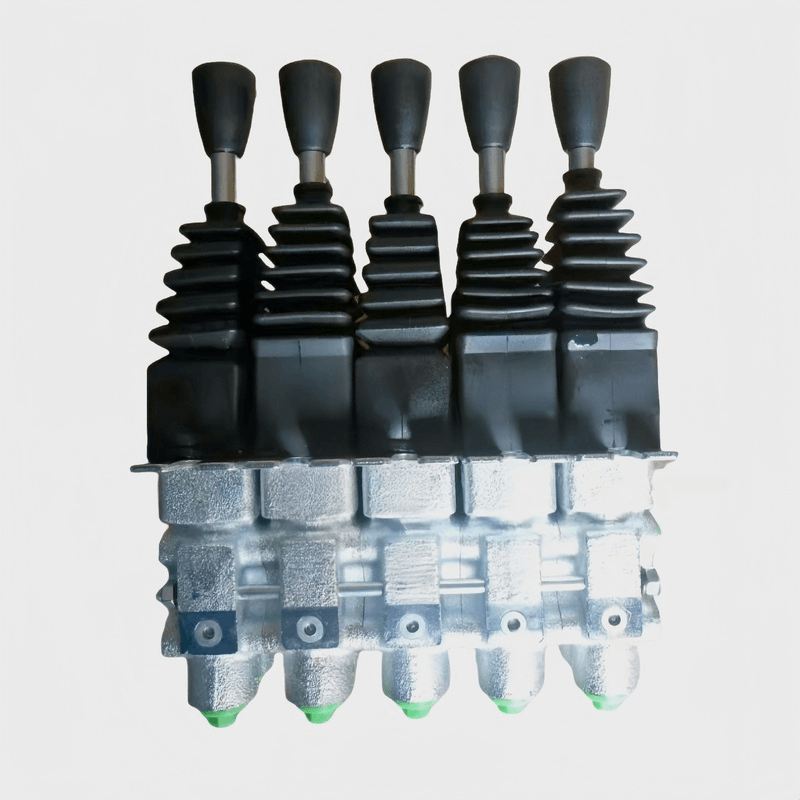

The Hydrocontrol HC-RCM/6 is a robust and ergonomic hydraulic joystick control lever designed to provide precise pilot operation in various mobile hydraulic applications.As a hydraulic pilot control lever,it translates the mechanical input from an operator into a proportional hydraulic signal,enabling smooth and accurate control of directional valves,variable pumps,or other hydraulic actuators.Engineered for reliability in harsh environments,this valve is a key interface in machinery ranging from compact excavators to agricultural equipment,ensuring low operating effort and high-performance feedback for the operator.

1.Product Overview&Operating Principle

The HC-RCM/6 belongs to a family of hydraulic pilot control lever products known for their durability and performance.It functions as a hydraulic joystick control that typically utilizes a switch-control valve mechanism to manage direction.Its core purpose is to offer precise pilot operation for directing hydraulic systems.

Core Function:The lever's movement actuates the valve inside,generating a hydraulic pilot signal.This signal is then used to control a larger,main hydraulic valve or a variable pump,allowing the operator to manage powerful machine functions—like a boom or an attachment—with minimal physical effort.

Ergonomic Design:The HC-RCM/6 is designed with operator comfort and efficiency in mind.It often features a well-contoured handle that fits naturally in the hand,reducing fatigue during long operating cycles.The low operating force required makes it ideal for applications requiring frequent and precise movements.

2.Technical Specifications

While specific datasheets for the HC-RCM/6 model are not available in the search results,its technical profile can be inferred from closely related models like the HC-RCM/1 and HC-RCX series.The following table outlines the expected parameters:

Parameter

Specification/Typical Value

Manufacturer Hydrocontrol

Product Type Hydraulic Pilot Control Lever/Joystick

Model HC-RCM/6

Rated Pressure~60 bar

Peak Pressure Up to~100 bar

Oil Flow Capacity~12 l/min

Operation Principle Switch Control Valve(for directional control)

Number of Stages Single-stage

Construction Material Cast Steel

Weight~2.5-10.0 kg(varies by exact configuration)

Note on Configuration:Hydrocontrol levers like the HC-RCM/6 are highly configurable.Parameters such as the control lever's length,the type of metering curve(which affects the progression of flow relative to lever movement),and the specification of the return spring can be tailored to the specific application.

3.Key Features&Components

The HC-RCM/6 integrates several design features that contribute to its performance and reliability:

Robust Construction:The valve body is typically made from cast steel,providing excellent strength and durability to withstand the vibrations and shocks common in mobile machinery.

Low Operation Force and Maintenance:A key design goal of this hydraulic joystick control is to minimize the force required by the operator,enhancing comfort and precision.This design also contributes to low energy consumption and reduced maintenance needs.

Modular Design Elements:Similar to other models in the series,the HC-RCM/6 likely features a modular design.This allows for different combinations of lever handles,spring-return mechanisms,and valve bodies to meet specific machine requirements and control feels.

Safety and Reliability:The design incorporates features to ensure safe operation.For instance,models can be specified with a spring-return mechanism that automatically brings the lever to a neutral position when released,a critical safety function for many machines.

4.Primary Applications&Use Cases

This hydraulic pilot control lever is suited for a wide array of mobile equipment where precise hydraulic control is paramount:

Compact and Mini Excavators:Used to control the travel,boom,arm,and bucket movements with fine precision.

Loaders and Skid-Steer Loaders:Provides intuitive control for lifting,tilting,and maneuvering attachments.

Agricultural Machinery:Applied in tractors and specialized agricultural equipment for controlling implements like front-end loaders or mowers.

Forestry and Specialized Vehicles:Its robustness makes it suitable for demanding applications in forestry machinery and other specialized industrial vehicles.

5.Expanded Perspective:Understanding Hydraulic Pilot Control Levers

To make an informed selection,it's helpful to understand the broader context of this technology and its role in hydraulic systems.

5.1 The Role of Pilot Operation in Hydraulics

A hydraulic pilot control lever is part of a two-stage control system:

Pilot Stage:The hydraulic joystick control itself is the pilot stage.It uses a small,easily managed hydraulic flow to generate a control signal.

Main Stage:This pilot signal then acts upon the main valve or pump,which controls the high-power flow to the hydraulic cylinders or motors.

This system allows for precise control of very large hydraulic forces with minimal operator effort,making it a cornerstone of modern mobile equipment design.

5.2 Advantages in System Design

Integrating a joystick like the HC-RCM/6 offers several system-level benefits:

Ergonomic Improvement:Directly reduces operator fatigue,which can lead to higher productivity and safer operation.

Design Flexibility:The valves can be remotely mounted,allowing for more flexible machine cab design and layout.

Smooth Control:The proportional nature of the pilot signal allows for smooth and gradual actuation of hydraulic functions,enabling fine control and reducing shock loads on the machine structure.

5.3 Selection and Sourcing Guidance

Identify Application Requirements:Determine the number of levers needed,the type of control(e.g.,spring-return,detent),the required physical lever length,and the operating pressure range.

Consult Technical Specialists:Given the configurable nature of these components,it is highly recommended to consult directly with Hydrocontrol or an authorized distributor.They can provide the definitive technical datasheet for the HC-RCM/6 and assist in selecting the correct options for your specific machine.

Verify Compatibility:Ensure the valve's pressure rating,flow capacity,and port threads are compatible with the rest of your hydraulic system.

6.Frequently Asked Questions(FAQs)

1.What is the main difference between the HC-RCM/6 and other models like HC-RCM/1?

The primary differences typically lie in the specific configuration,which can include the type of handle,the length of the lever,the characteristics of the return spring,and the metering curve of the valve.These variations tailor the joystick's feel and performance to different machines and operator preferences.

2.Can the HC-RCM/6 be used to control a variable displacement pump?

Yes,absolutely.One of the primary applications of a proportional hydraulic pilot control lever like the HC-RCM/6 is to provide the control signal for variable pumps,enabling seamless control of machine speed and power.

3.What does the"metering curve"specification mean?

The metering curve(e.g.,"A01"or"A02")defines the relationship between the lever's displacement and the resulting hydraulic flow output.A linear curve provides a direct relationship,while other curves might offer more sensitivity at the beginning of the movement or other progression characteristics,affecting the"feel"and precision of control.

4.Is this valve suitable for extremely rugged environments?

Yes.The use of cast steel for construction and the design intent for off-highway machinery make the HC-RCM/6 suitable for demanding conditions involving dust,moisture,and mechanical vibration.

5.Where can I find the definitive technical datasheet for this model?

For accurate and complete technical specifications,installation dimensions,and ordering codes for the HC-RCM/6,you should contact Hydrocontrol directly or one of their authorized distributors.They can provide the official documentation to ensure correct selection and integration.