1 Product Introduction and Core Technology

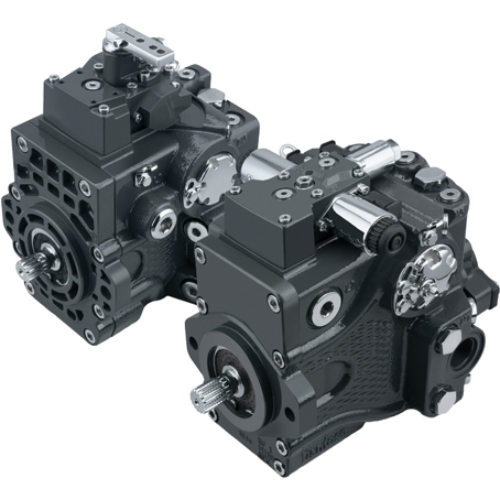

The Danfoss MP1 represents a significant evolution in axial piston pump technology,specifically engineered for closed-circuit applications in mobile hydraulics.This hydraulic piston pump is designed to meet the demanding performance requirements of modern medium and small-sized equipment across various industries,embodying Danfoss's long-standing commitment to the mobile hydraulic sector.The MP1 series is not merely an incremental improvement but a comprehensive re-imagining of pump design,focusing on modularity,efficiency,and integration ease to serve as a versatile power source for a multitude of machinery.

At its core,the MP1 operates on the axial piston principle,where multiple pistons arranged in a circular pattern within a cylinder block create the pumping action through their reciprocating motion against a swash plate.This fundamental design is enhanced with state-of-the-art components and servo systems that elevate its performance beyond conventional pumps.The pump's architecture is meticulously crafted to deliver reliable operation while maintaining compact dimensions,making it an ideal choice for equipment manufacturers facing spatial constraints in their machine designs.

The development of the MP1 pump draws upon Danfoss's extensive experience spanning over four decades in creating advanced components and systems for off-road mobile machinery worldwide.This heritage of engineering excellence is evident in every aspect of the MP1's design,from its robust construction to its sophisticated control options.The pump represents what Danfoss describes as"the next generation"of hydraulic pumps,incorporating forward-thinking technologies that address both current and future needs of equipment manufacturers.

2 Technical Specifications and Performance Parameters

The Danfoss MP1 axial piston pump series offers multiple displacement options to accommodate varying application requirements,primarily including 28/32 cm³and 38/45 cm³models.This dual-displacement approach within the same basic platform provides manufacturers with configuration flexibility without necessitating significant design changes.The pump operates at a maximum continuous speed of 500 RPM for the 28/32 model and can handle intermittent pressures up to 4000 bar,demonstrating its capability for demanding hydraulic applications.

Regarding physical characteristics,the MP1 pump features remarkably compact dimensions,with the 28/32 cm³model measuring approximately 206 mm in length and weighing 29.6 kg.This compact form factor is a deliberate design choice to address the space constraints commonly encountered in mobile equipment.The pump's construction utilizes high-strength materials and precision machining to ensure durability while maintaining manageable weight characteristics,contributing to easier installation and integration into machine designs.

The operational parameters of the MP1 hydraulic piston pump include a maximum operating pressure of 350-380 bar,depending on the specific model and configuration.The pump requires a minimum case pressure of 3-5 bar for proper operation and can tolerate maximum case pressures of 10 bar,ensuring reliable performance across diverse operating conditions.These specifications position the MP1 as a robust solution for medium-duty applications requiring consistent hydraulic power delivery in challenging environments.

3 Design Features and Engineering Innovations

3.1 Modular Design Philosophy

The Danfoss MP1 incorporates a sophisticated modular design that sets it apart from conventional axial piston pump options.This modular approach enables manufacturers to select from various control modules,charge pumps,and auxiliary flange options while maintaining a standardized base platform.The strategic implementation of modularity allows for quick and straightforward reconfiguration of the pump to meet specific application requirements,significantly reducing engineering overhead and time-to-market for equipment manufacturers.

This modular architecture extends to the pump's control options,which encompass a comprehensive range including electro-hydraulic controls such as Electric Displacement Control(EDC),Electric Three-Position Control(FNR),and manual alternatives like Manual Displacement Control(MDC).The consistency of control modules across the entire MP1 series streamlines the design process for OEMs working with multiple pump sizes,as similar interfaces and mounting configurations can be maintained regardless of the specific pump displacement selected.

3.2 Advanced Engineering Components

Danfoss has integrated several patented technologies into the MP1 hydraulic piston pump to enhance its performance and reliability.The pump incorporates a specialized servo guide lever system combined with durable tapered roller slewing bearings that significantly reduce vibration while enabling precise machine control.This innovative approach to managing the swash plate movement results in smoother operation,greater predictability,and enhanced safety in machine functions.

The MP1 also features industry-leading rotating group technology that optimizes efficiency throughout the operating range,directly contributing to lower total cost of ownership.The implementation of low-friction slewing bearings ensures predictable and precise machine control while minimizing energy losses.Additionally,the pump's clean-side design with no customer interfaces and integrated loop flush capability(available on 28/32 cc models)provides greater flexibility in component placement within the machine layout.

4 Application Areas and Industry Solutions

The Danfoss MP1 axial piston pump finds application across diverse mobile equipment sectors,demonstrating its versatility and adaptability to different operational requirements.In road construction equipment,the pump's rugged design and durability make it suitable for the harsh conditions encountered in compactors,pavers,and milling machines.The pump's precise control capabilities ensure consistent performance even under varying load conditions,contributing to improved quality in road surface finishing.

For material handling equipment such as forklifts,small cranes,and conveyor systems,the MP1's compact dimensions and compatibility with Danfoss's PLUS+1®control system enable precise movement control and smooth operation.The pump's modularity allows equipment manufacturers to tailor the hydraulic system to specific lifting,lowering,and positioning requirements without necessitating fundamental changes to the power unit design.

The MP1 series also serves specialized applications in turf maintenance equipment,agricultural machinery,and unique mobile platforms.In these contexts,the pump's ability to be configured with exactly the right control features—whether MDC,EDC,or HDC—provides manufacturers with the flexibility to scale functionality according to application needs and market demands.This application-specific approach to pump configuration ensures optimal performance while maintaining cost-effectiveness across different equipment tiers and market segments.

5 Performance Advantages and Operational Benefits

5.1 Enhanced Efficiency and Control Precision

The Danfoss MP1 axial piston pump delivers exceptional operational efficiency through its advanced rotating group technology and optimized fluid dynamics.This efficiency translates directly into reduced fuel consumption for engine-driven equipment and lower energy costs for electrically powered machinery,providing significant lifetime operational savings.The pump's design minimizes internal losses while maintaining consistent performance across its entire operating range,ensuring that efficiency is maintained not just at ideal conditions but throughout typical work cycles.

Control precision represents another significant advantage of the MP1 series,with its patented servo guide lever system enabling exceptionally accurate machine control.This precision manifests in smoother operation,more predictable equipment behavior,and enhanced operator comfort—particularly important in applications requiring fine movements or precise positioning.The low hysteresis and high sensitivity of the control system contribute to this precise controllability,allowing operators to make minute adjustments with confidence in the equipment's response.

5.2 Integration Flexibility and Serviceability

The compact dimensions of the MP1 hydraulic piston pump,particularly its industry-leading short length,provide substantial advantages for equipment designers working within tight space constraints.This compact footprint enables more flexible machine layouts or the accommodation of additional functionality within the same envelope.The pump's clean-side design with no customer interfaces further simplifies integration,reducing installation time and potential leak points.

Serviceability is enhanced through the pump's modular construction,which allows for component-level replacement and straightforward field maintenance.The standardization of parts across different displacements within the MP1 series simplifies inventory management for service providers and equipment manufacturers.Additionally,the comprehensive diagnostic capabilities facilitated by compatibility with Danfoss's PLUS+1®platform enable predictive maintenance approaches,potentially reducing unplanned downtime and extending component life through proactive intervention.

6 Industry Context and Future Developments

The Danfoss MP1 exists within an evolving landscape of hydraulic technology that increasingly emphasizes connectivity,efficiency,and integration with electronic control systems.Danfoss has demonstrated commitment to these trends through developments such as the recently introduced Hybrid Load Control system for its H1P and MP1P hydraulic pumps.While this specific technology currently targets the MP1P series,it indicates the direction of innovation within Danfoss's product ecosystem and potentially foreshadows future enhancements to the MP1 platform.

The growing importance of digitalization in mobile equipment is reflected in MP1's compatibility with Danfoss's PLUS+1®platform,which supports the entire software development process and can reduce development time by up to 55%according to company claims.This integration capability positions the MP1 pump as a forward-looking component in increasingly connected equipment architectures,where hydraulic systems must seamlessly interface with electronic controls and telematics systems.

Danfoss's global presence and application support infrastructure,including facilities like the Haiyan ADC Application Development Center in China,provide localized technical support and testing capabilities for customers implementing MP1-based systems.This support network ensures that manufacturers can access expertise for optimizing pump performance within their specific applications,potentially accelerating development cycles and enhancing final product performance.

Frequently Asked Questions(FAQs)

What industries commonly utilize the Danfoss MP1 axial piston pump?

The MP1 pump serves a diverse range of mobile equipment sectors,with particular prominence in road construction machinery(compactors,pavers),material handling equipment(forklifts,small cranes),agricultural machinery,turf maintenance equipment,and specialized mobile platforms.Its balanced combination of performance,compact dimensions,and configuration flexibility makes it suitable for medium-duty applications across these industries.

How does the modularity of the MP1 pump benefit equipment manufacturers?

The MP1's modular design enables manufacturers to select from various control modules,charge pumps,and auxiliary flanges while maintaining a standardized base platform.This approach significantly reduces engineering overhead and simplifies inventory management,as common components can be used across multiple machine models.The modularity also facilitates quicker configuration changes and prototype development,accelerating time-to-market for new equipment designs.

What control options are available for the MP1 hydraulic piston pump?

The MP1 series offers comprehensive control options including electro-hydraulic controls such as Electric Displacement Control(EDC),Electric Three-Position Control(FNR),and No-Feedback Proportional Electric control(NFPE).Manual alternatives include Manual Displacement Control(MDC),while hydraulic control options include No-Feedback Proportional Hydraulic control(NFPH).This range of controls enables manufacturers to select the optimal interface for their specific application requirements and cost targets.

What advantages does the MP1 pump offer for equipment operating in harsh environments?

The MP1 incorporates several design features that enhance durability in challenging operating conditions.Its robust construction,advanced rotating group technology,and patented servo guide lever system with tapered roller slewing bearings provide reliable operation with minimal vibration.The pump's clean-side design with no customer interfaces reduces potential leak points,while its tolerance for varying operating conditions ensures consistent performance in demanding environments.

How does the MP1 pump contribute to overall system efficiency in mobile equipment?

The MP1 enhances system efficiency through several mechanisms,including its industry-leading rotating group technology that minimizes internal losses,reduced control pressures that decrease power consumption,and optimized fluid dynamics that improve overall volumetric efficiency.These efficiency gains translate directly to reduced fuel consumption in engine-powered equipment and lower operating costs over the equipment lifecycle.