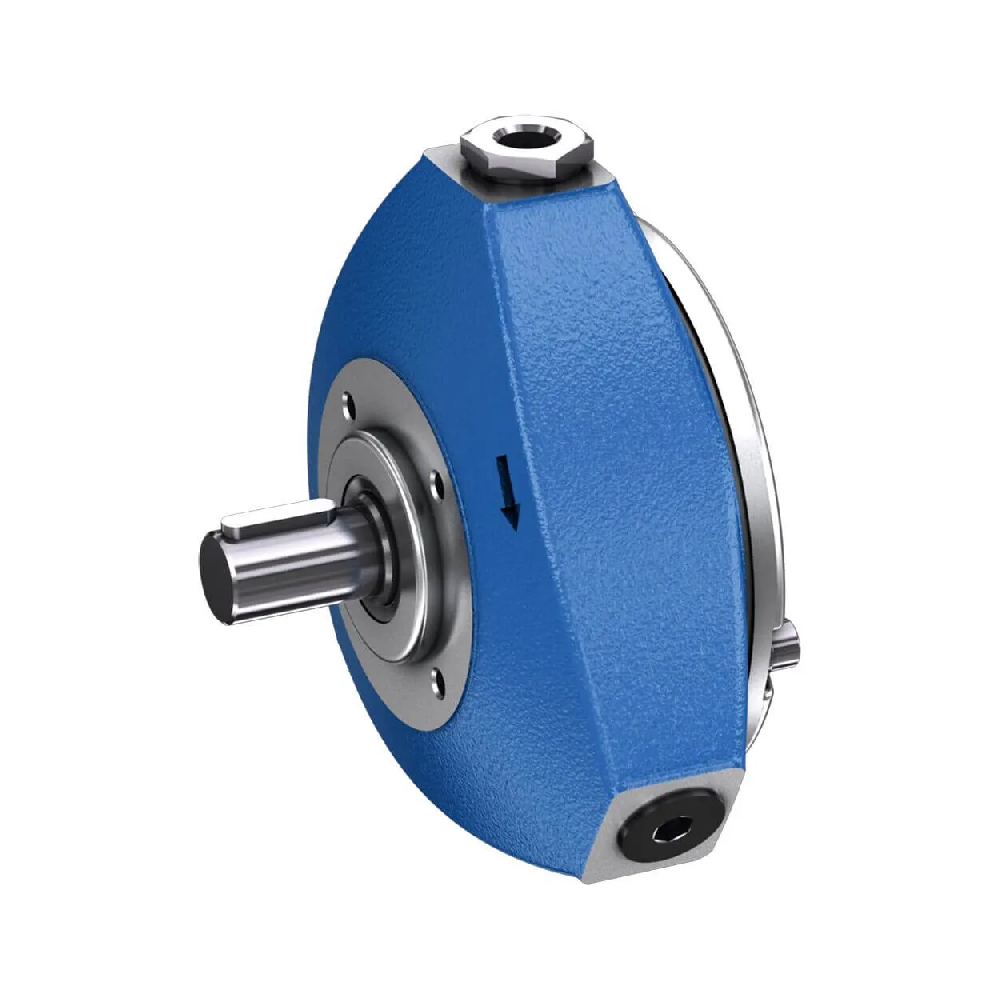

The Rexroth PR4-3X/2,00-700RA01M01 is a quintessential example of robust and reliable hydraulic power generation,embodying the core principles of a fixed displacement piston pump with a specific radial piston hydraulic pump architecture.This model is engineered for industrial applications where extreme pressure,unwavering reliability,and compact design are non-negotiable.As a valve-controlled,self-priming pump,it delivers a constant flow output capable of sustaining a maximum operating pressure of 700 bar,making it an indispensable component in high-pressure hydraulic systems for machine tools,plastic machinery,and testing equipment.Its radial piston design,where the pistons are arranged perpendicular to the drive shaft,distinguishes it from axial piston units and is key to its ability to generate such immense pressures within a compact envelope.

1.In-Depth Product Overview and System Integration Philosophy

The PR4 series,to which this model belongs,is defined by its fixed displacement characteristic,meaning its output flow is directly proportional to the speed of its drive shaft.The PR4-3X/2,00-700RA01M01 is designed for open-loop circuits and is renowned for its immediate operational readiness and simplicity of integration.The"3X"in its model number denotes its component series,indicating specific installation and connection dimensions,while the"2,00"specifies a nominal displacement of 2.00 cm³per revolution.This pump is not just a component;it is a system core,often serving as the high-pressure stage in complex systems or as a standalone reliable power source for less complex but demanding machinery.Its design philosophy prioritizes minimal maintenance,long service life,and ease of installation in space-constrained industrial environments.

2.Detailed Operational Principle and Fluid Dynamics

The operational genius of this radial piston hydraulic pump lies in its straightforward and robust mechanism.The pump features three pistons arranged radially around a central eccentric shaft.As the eccentric shaft rotates,it imparts a reciprocating motion to each piston.

Suction Phase:During the piston's outward stroke,the volume within its chamber increases,creating a vacuum.This vacuum draws hydraulic fluid from the inlet port,lifting the suction valve off its seat and allowing fluid to fill the chamber.

Pressure Phase:As the piston reverses direction and moves inward,the suction valve closes due to the increasing pressure.The fluid is then compressed until it forces the pressure valve open,directing the high-pressure fluid into the system's discharge line.

This valve-controlled design,as opposed to a slipper pad design found in many axial piston pumps,is a key factor in its ability to achieve and maintain ultra-high pressures of 700 bar with exceptional reliability and low internal leakage.The use of three pistons contributes to a relatively smooth flow output,which is a notable achievement for a pump of this compact size and pressure rating.

3.Comprehensive Technical Specifications and Performance Envelope

The Rexroth PR4-3X/2,00-700RA01M01 is defined by a set of impressive technical parameters that outline its high-performance capabilities.

Displacement and Flow:The pump has a fixed nominal displacement of 2.00 cm³/rev.The maximum theoretical flow rate is therefore a direct function of the driven speed;for instance,at 1500 rpm,the theoretical flow would be 3.0 L/min.

Pressure Capability:This is a standout feature,with a maximum allowable operating pressure of 700 bar.This makes it suitable for the most demanding high-force applications.

Drive and Shaft Configuration:The pump is designed to be driven by an external prime mover.It features a cylindrical shaft end measuring 25 mm in diameter with a feather key,complying with ISO 3019-2 standards,ensuring easy coupling and standardization.

Physical Construction and Sealing:The pump body is constructed from cast iron,providing the necessary strength and durability to withstand high internal pressures and resist deformation.Standard sealing is achieved with NBR(Nitrile Butadiene Rubber)seals,which offer a good balance of compatibility with standard mineral-based hydraulic oils and cost-effectiveness.The unit has a weight of approximately 9.25 kg,reflecting its dense and robust construction.

4.Distinctive Design Features and Engineering Advantages

The Rexroth PR4-3X/2,00-700RA01M01 incorporates several design features that contribute directly to its operational advantages in the field.

Extreme Pressure Competence:The core advantage of this radial piston hydraulic pump is its ability to operate continuously at 700 bar.This is achieved through its robust radial piston design,high-strength materials,and valve-controlled operation,which is inherently well-suited for sealing at extreme pressures.

Compact and Space-Efficient Footprint:The radial configuration allows for a very compact and short axial length compared to many axial piston pumps of similar pressure rating.This is a critical benefit for machine designers working with limited installation space.

Long Service Life and Reliability:The pump utilizes hydraulically lubricated plain bearings for its critical rotating components.This fluid-film lubrication results in minimal wear,contributing to an exceptionally long operational lifespan,even under continuous high-load conditions.

Low Noise Operation:Despite its high-pressure capability,the pump is engineered for relatively quiet operation.This is a significant consideration for improving the working environment in industrial settings and meeting occupational health and safety standards.

5.Primary Industrial Applications and Sector-Specific Solutions

The combination of high pressure,compactness,and reliability makes this fixed displacement piston pump a preferred choice across a diverse range of heavy-duty industries.

Machine Tool and Metal Forming:It is ideally suited for powering the clamping cylinders in high-precision machining centers and the main actuators in hydraulic presses,where immense,unwavering force is required.

Plastic and Injection Molding Machinery:The pump provides the high-pressure hydraulic power necessary for the clamping units of injection molding machines,ensuring mold integrity and product quality during the injection cycle.

Test and Simulation Equipment:In hydraulic test benches and material testing systems,the pump's ability to generate and maintain precise,ultra-high pressures is invaluable for simulating real-world stress conditions.

General Industrial Hydraulics:Its application extends to various other sectors,including automotive manufacturing,wood processing,and printing presses,wherever a reliable and compact high-pressure hydraulic source is needed.

6.Comparative Advantages and Economic Value Proposition

Choosing the Rexroth PR4-3X/2,00-700RA01M01 offers several tangible benefits that translate into long-term value.

Operational Reliability in Harsh Conditions:The pump's simple,robust design with minimal moving parts and plain bearing technology makes it exceptionally reliable,reducing the risk of unplanned downtime in critical production processes.

Reduced Total Cost of Ownership:While the initial investment might be higher than some alternatives,the pump's long service intervals,durability,and energy-efficient operation(due to high volumetric efficiency at high pressure)contribute to a lower total cost of ownership over its lifecycle.

Simplified System Architecture:As a fixed displacement piston pump,it requires no complex control systems for displacement variation.This simplifies the overall hydraulic circuit design,reduces the number of ancillary components needed,and makes the system easier to maintain and troubleshoot.

Expanded Perspective:The Strategic Role of Fixed Displacement Radial Piston Pumps

Understanding the niche and selection criteria for this type of pump is crucial for optimal system design.

1.Application Philosophy:When to Choose a Fixed Displacement Radial Piston Pump

The decision to use a pump like the PR4-3X/2,00-700RA01M01 is driven by specific application requirements.

The primary trigger is the need for system pressures exceeding 400 bar.While axial piston and vane pumps are common,they often have lower maximum pressure ratings.The radial piston design is inherently stronger for pressure containment.

It is the ideal choice when the hydraulic system's flow demand is relatively constant or when flow control can be efficiently managed through other means,such as using a frequency converter on the electric motor drive.

This pump is also selected for applications where space,particularly axial length,is a major constraint,and where operational noise levels are a concern.

2.Critical Considerations for System Design and Implementation

Successfully integrating this high-pressure pump requires careful attention to system details.

Filtration is Paramount:To protect the precise mating surfaces of the pistons and valves from abrasive wear,a high-pressure filter with a fine rating is absolutely essential.Maintaining fluid cleanliness is the single most important factor for ensuring the pump's longevity.

Drive and Coupling Alignment:The pump must be driven by a prime mover with adequate power and torque.The coupling between the motor and the pump shaft must be precisely aligned to prevent premature bearing and shaft seal failure.

Fluid Compatibility and Temperature Control:While the standard NBR seals are suitable for mineral oils,alternative seal materials like FKM(Viton)are available for different fluid types.The system must also be designed to control oil temperature within an optimal range to maintain fluid viscosity and seal integrity.

Frequently Asked Questions(FAQs)

What is the key functional difference between a radial and an axial piston pump?

The fundamental difference lies in the piston arrangement.In a radial piston hydraulic pump like the PR4 model,the pistons are arranged perpendicular(radially)to the drive shaft,moving in and out against an eccentric.In an axial piston pump,the pistons are arranged parallel to the drive shaft and reciprocate by running against a tilted swashplate.The radial design is often more compact in length and can be more robust for very high-pressure applications,while axial designs are typically more suited for variable displacement and higher speeds.

Is this pump suitable for mobile machinery applications?

While primarily designed for industrial applications,this pump can be used in mobile equipment if the specific requirements align.However,its fixed displacement characteristic means it cannot vary flow output with shaft speed constant,which is often a desired trait in mobile hydraulics.For mobile applications with fluctuating flow demands,a variable displacement pump would generally be more energy-efficient.

How does the'valve-control'mechanism contribute to the pump's high-pressure capability?

The valve-control mechanism,using discrete suction and pressure valves for each piston,creates a very positive seal during the compression phase.Unlike the port plate design used in many axial piston pumps,which relies on very fine tolerances,the seated valves are less susceptible to internal leakage at extreme pressures.This design is a key enabler for the pump's 700-bar performance.

What maintenance practices are critical for ensuring the long service life of this pump?

The most critical practice is maintaining excellent hydraulic fluid cleanliness.Regularly monitoring and replacing high-pressure filters is essential.Additionally,ensuring proper alignment of the drive coupling,checking for external leaks,and monitoring the system's operating temperature will help prevent premature failure.The pump's plain bearings are lubricated by the hydraulic fluid itself,so maintaining the correct fluid viscosity and quality is paramount for their lifespan.

Can this pump be used with bio-degradable or high-water-content fluids?

The standard version with NBR seals is not compatible with high-water-content fluids like HFA,HFB,or HFC.For use with these or certain biodegradable oils,the pump would need to be specified with alternative seal materials,such as FKM(Viton),at the time of ordering.It is crucial to consult the manufacturer's specifications for fluid and seal compatibility for non-standard applications.